Professional LG Washing Machine Service in Chennai - Expert Doorstep Repair

AWhen your LG washing machine requires professional attention, trust Chennai's most reliable lg washing machine service in Chennai experts. Our certified technicians provide comprehensive repair and maintenance services for all LG washing machine models across Chennai, ensuring your appliance operates at peak performance.

As the most trusted LG washing machine service in Chennai, we specialize in repairing all LG washing machine models including:

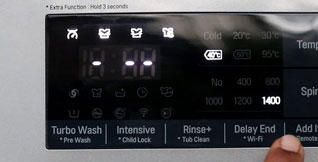

LG Front Load Washing Machine Repair Chennai

LG Top Load Washing Machine Service Chennai

LG Semi-Automatic Washing Machine Repair

LG Fully Automatic Washing Machine Service

LG Direct Drive Washing Machine Repair

LG Turbo Drum Washing Machine Service

Why Choose Our LG Service Center Chennai?

Same Day Service

Quick response within 60 minutes across all Chennai locations, minimizing disruption to your daily routine.

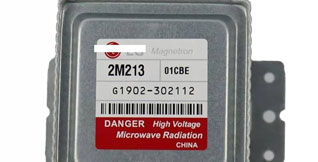

Genuine LG Parts

We use only authentic LG components to ensure optimal performance and longevity of your washing machine.

Expert Technicians

Our expert team specializes exclusively in LG washing machine repairs, with extensive training on all models.

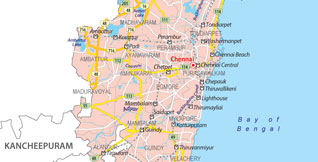

All Chennai Areas

Service available in every corner of Chennai

Transparent Pricing

Fixed service charges of ₹399 with no hidden costs. If you proceed with the repair, inspection charges are waived.

3 Month Warranty

All repairs come with up to 3 months warranty on parts and service, providing complete peace of mind.

24/7 Emergency Service

Available for urgent washing machine breakdowns

Doorstep Service

No need to carry your washing machine anywhere

Common LG Washing Machine Problems We Fix in Chennai

Our lg washing machine service in chennai covers all major issues you might encounter:

Water Not Filling

Inlet valve problems, clogged filters, or pressure switch malfunctions

Water Not Draining

Blocked drain pump, clogged filters, or damaged drainage system

Water Leakage

Door seal damage, loose connections, or internal piping issues

Too Much Water in Tank

Pressure sensor calibration

Not Spinning

Motor and belt repair

Drum Not Rotating

Motor coupling failure, drive belt issues, or tachometer problems

Unusual Noise During Spin

Drum bearing replacement

Clothes Not Drying Properly

Spin cycle optimization

Not Starting

Power and control board repair

Display Not Working

PCB and LED panel replacement

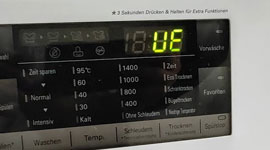

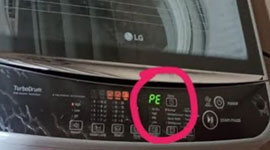

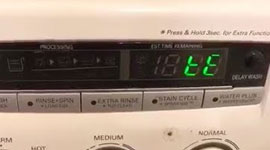

Error Codes Appearing

Professional diagnosis and repair

Door Not Locking

PCB and LED panel replacement

Not Heating Water

Heating element replacement

Temperature Sensor Malfunction

Sensor calibration and repair

Overheating Issues

Thermostat and control repair